|

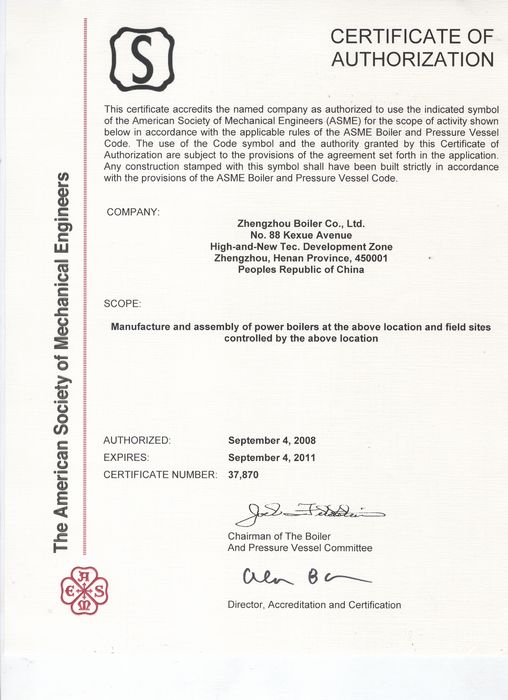

Zhengzhou Boiler Co., Ltd.

|

blown gas waste heat boiler

| Payment Terms: | T/T,L/C |

| Special Groups: |

steam boilers (44)

|

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Three Castoff Mix Burning and Blown Gas Waste Heat Boile has the advantages of little investment in construction

15-75t/h

1.25-9.8mpa

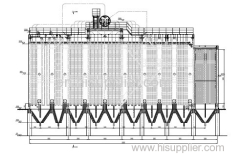

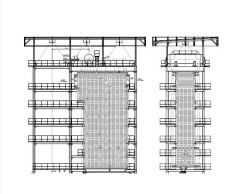

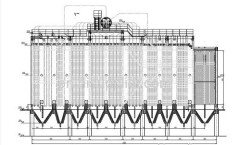

Three Castoff Mix Burning and Blown Gas Waste Heat Boiler and blown gas waste heat boiler are ideal equipment of high efficiency and energy-saving in fertilizer and chemicals (esp. methanol, ethanol, formaldehyde, synthetic ammonia) industry. According to the features of waste heat flue gas of this industry, the three castoff mix burning and blown gas waste heat boiler developed by our company mainly can be divided into two types of natural circulation waste heat boilers: vertical type and tunnel kiln horizontal type. This waste heat boiler is typical energy-efficient equipment in chemical circular economy; the three castoff mix burning and blown gas waste heat boiler can support the three castoff burning boiler and blown gas waste heat boiler and hel the production enterprise to completely realize ombining two kinds of coal to one, and two boilers to one, the three castoff mix burning and blown gas waste heat boiler produce great economic benefits and environmental protection benefits for the enterprises and thoroughly achieving the goal of safety, environmental protection, improving of output and efficiency, and energy saving.

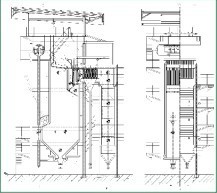

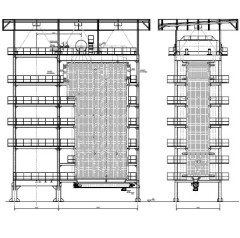

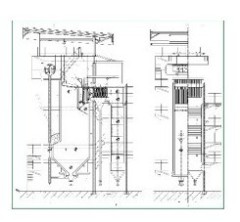

Three Castoff Mix Burning and Blown Gas Waste Heat Boiler consists of main heating surfaces like water-cooling panel,super-heater,convection tube-bank,coal-saving machine and air pre-heater etc.they have the following advantages:

1.The heating surface of the boiler employs suspension strucyure wich is good for absorbing boiler expansion and is of high operation safety.

2.The boiler uses special sealing devices to reduce boiler air leakage and improve boiler efficiency

3. The heating surfaces of the boiler employs reasonable flue gas velocity design to prevent soot accumulation

4. The boiler adopts straight-through arrangement wich can use deadweight of soot to self-remove soot and keep the heating surface clean,and improve the heat exchange efficiency of the boiler.

5. The boiler properly organizes flue gas dynamical field to keep steady and uniform flow of flue gas and avoid deflection,applying sole wear-resisting structure to avoid boiler arasion and longer boiler lifetime at the saME TIME

6.the boiler convection tube-bank employs assembled structure with short installation period and low costs.And the vertical waste heat boiler has the advantages of small floor area,little investment in construction,high heat exchange efficiency and strong soot self-cleaning capability and so on

The main specifications are as following:rated steam output 15-75t/h rated steam pressure 1.25-9.8MPa

Three Castoff Mix Burning and Blown Gas Waste Heat Boiler consists of main heating surfaces like water-cooling panel,super-heater,convection tube-bank,coal-saving machine and air pre-heater etc.they have the following advantages:

1.The heating surface of the boiler employs suspension strucyure wich is good for absorbing boiler expansion and is of high operation safety.

2.The boiler uses special sealing devices to reduce boiler air leakage and improve boiler efficiency

3. The heating surfaces of the boiler employs reasonable flue gas velocity design to prevent soot accumulation

4. The boiler adopts straight-through arrangement wich can use deadweight of soot to self-remove soot and keep the heating surface clean,and improve the heat exchange efficiency of the boiler.

5. The boiler properly organizes flue gas dynamical field to keep steady and uniform flow of flue gas and avoid deflection,applying sole wear-resisting structure to avoid boiler arasion and longer boiler lifetime at the saME TIME

6.the boiler convection tube-bank employs assembled structure with short installation period and low costs.And the vertical waste heat boiler has the advantages of small floor area,little investment in construction,high heat exchange efficiency and strong soot self-cleaning capability and so on

The main specifications are as following:rated steam output 15-75t/h rated steam pressure 1.25-9.8MPa

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Gas Boiler

Waste Heat Boilers

Waste Heat Generator

Boiler Gas Valve

Exhaust Gas Boiler

Oil Gas Fired Boiler

More>>