|

Zhengzhou Boiler Co., Ltd.

|

Water Tube Waste Heat Boilers

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Water Tube Waste Heat Boilers cover a smaller area,needs less investment,is brand new and has advanced properties.

2-130t/h

Usage:Industrial

Water Tube Waste Heat Boilers cover a smaller area,needs less investment,is brand new and has advanced properties.

Products relying on a strong technical backing, in order to "health world, future" as the enterprise idea, with energy conservation and environmental protection products and services in health, laboratory and other high-end technology, for human health and the health of the world, set up the green channel, we have to "abide by the laws, the good faith management, quality first" as the basic principle, in order to "serve the society, the harmonious environment" as the professional attitude, efforts to create "health product", to provide customers with quality service.

2-130t/h

Usage:Industrial

Water Tube Waste Heat Boilers cover a smaller area,needs less investment,is brand new and has advanced properties.

2-130t/h

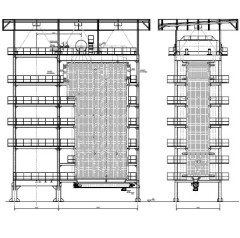

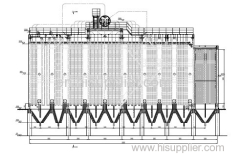

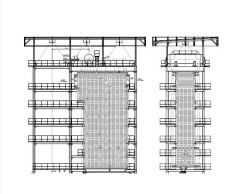

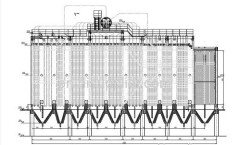

Carbon rotary kiln waste heat boiler of this industry includes two series of natural circulation water-tube waste heat boilers: carbon rotary kiln waste heat boiler and tank carbon waste heat boiler With vertical II structure,Water Tube Waste Heat Boilers the structure of Carbon rotary kiln waste heat boiler is brand new and has advanced properties. It is original throughout China and is a new-type carbon rotary kiln waste heat boiler developed independently by this company.

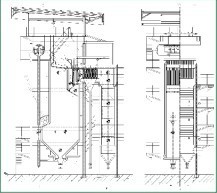

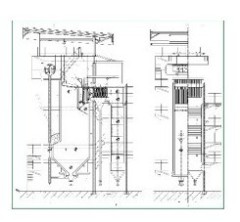

The flue gas is discharged from the boiler through boiler slag screen, Water Tube Waste Heat Boilers super heater, convection tube tank and steel tube economizer.Water Tube Waste Heat Boilers The carbon rotary kiln waste heat boiler slag screen of the boiler is lengthened from the front water wall tube. The filter is horizontal pendant structure, constituted by high temperature section and low tank is in-line pitching. Flue gas twice baffle plate is adopted to enhance the flue gas speed and form horizontal scouring, so the heat transfer capacity of convection tube tank is improved. Economizer employs S-shaped tube, and has horizontal scouring staggered arrangement. The central part of water-enlarged, but both the sealing and safety are improved. The front and back water wall also adopts membrane-type water wall.

This boiler structure, compared with traditional carbon rotary kiln waste heat boiler, covers a smaller area, needs less investment, is brand new and has advanced properties. It is of leading level in China and is a new milestone in the development of carbon rotary kiln waste heat boiler.

The main specifications are as following: rated steam output 2-130t/h, rated steam pressure 0.6-9.7Mpa.

Products relying on a strong technical backing, in order to "health world, future" as the enterprise idea, with energy conservation and environmental protection products and services in health, laboratory and other high-end technology, for human health and the health of the world, set up the green channel, we have to "abide by the laws, the good faith management, quality first" as the basic principle, in order to "serve the society, the harmonious environment" as the professional attitude, efforts to create "health product", to provide customers with quality service.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Waste Heat Boilers

Gas Water Boilers

Waste Heat Generator

Boilers

Waste Water Pump

Waste Water Treatment

More>>