|

Zhengzhou Boiler Co., Ltd.

|

Vertical 7.5t/h Waste Heat Boilers

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Vertical 7.5t/h Waste Heat Boilers are designed for vertical natural circulation waste heat boiler.

Type:natural circulation

Vertical 7.5t/h Waste Heat Boilers are designed for vertical natural circulation waste heat boiler.

Type:natural circulation

Vertical 7.5t/h Waste Heat Boilers are designed for vertical natural circulation waste heat boiler. The heat isflue gas discharged hazardous waste incineration

Features of 7.5t/h Waste Heat Boiler is:

1.energy-saving to achieve thermal energy utilization. Waste Heat Boiler is to use micro-dust concentrationin flue gas remaining heat of waste recycling systems can be used for power generation, production, life ofsuperheated steam.It does not use disposable fuel, so it has the characteristics of energy-saving andcomprehensive utilization of energy.

2.furnace dust. it is conducive to environmental protection.

Due to the flue gas contains large amounts of coarse dust, the boiler uses combined inertia separationprinciple and gravitational separation principle to achieve separation of dust, reducing soot content.

3. low resistance, running economy.

Waste Heat Boiler heating surface by adjusting the flow rate of flue gas flow cross-sectional area to achievethe design, reducing the bulk resistance, conducive to the integration with other devices and reduce systempower consumption.

4. compact.it looks neat in appearance.

Basic characteristics ofVertical 7.5t/h Waste Heat Boilers

Design features of 7.5t/h Waste Heat Boiler

Basic characteristics ofVertical 7.5t/h Waste Heat Boilers

1.boiler specification

rated evaporation 7.5t/h

rated steam temperature 204.3℃

rated steam pressure 1.6MPa

feed water temperature 104℃

exhaust gas temperature 550℃

import of boiler flue gas 20350Nm3/h

import of boiler flue gas temperature 1130℃

import of boiler flue gas dust content 2.5g/Nm3

2.flue gas content(%):

(1) CO2 8.38

(2) H2O 10.73

(1) CO2 8.38

(2) H2O 10.73

(3) O2 8.98

(4) N2 71.91

(5)HCL <900mg/ Nm3

(6)SO2 <1500mg/ Nm3

(6)SO2 <1500mg/ Nm3

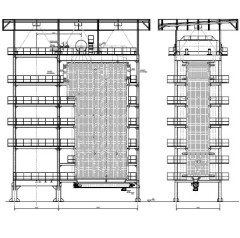

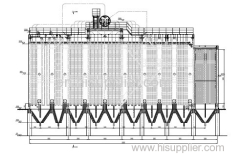

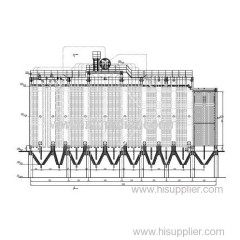

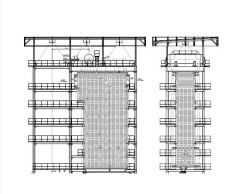

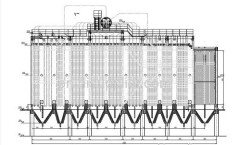

3.boiler basic dimensions

boiler width (centerline distance of about two left and right columns) 6000mm

boiler depth(centerline distance of about two front and back columns) 16830mm

drum elevation 21350mmDesign features of 7.5t/h Waste Heat Boiler

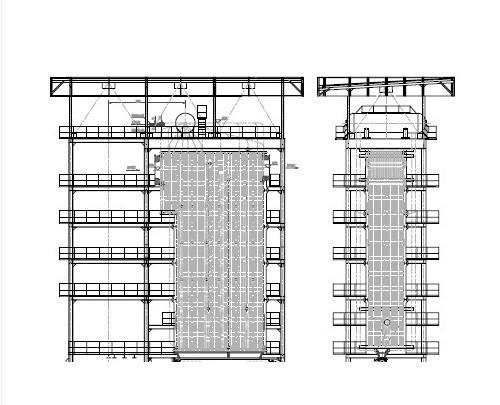

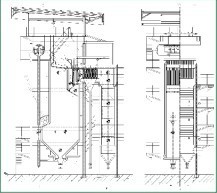

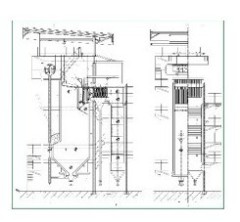

Vertical 7.5t/h Waste Heat Boilers are verticalnatural circulation. The heat from the boiler is flue gas which isdischarged from hazardous waste incineration.Vertical 7.5t/h Waste Heat BoilersBoiler feed water temperature is 104 ℃.Working fluid directlyinto the drum, and then from the drumdown pipe flows through the membrane wall, Vertical 7.5t/h Waste Heat Boilers where after beingheated steam conduit reintroduction drum, and then separated by soda leads to saturated steam from thesteam drum.

Vertical 7.5t/h Waste Heat Boilers heating surface adopts membrane wall structure, the pipe diameter is Φ60.Membrane wall is left on the hole, blowing holes . the user adopts sootblowers according to specificcircumstances. Boiler furnace wall select light furnace wall.

Structure introduction ofVertical 7.5t/h Waste Heat Boilers

Structure introduction ofVertical 7.5t/h Waste Heat Boilers

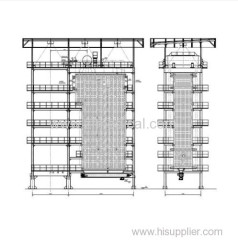

1.Drum

Drum diameter isФ1500.Material of drum is 20g.The main equipment in the boiler is underwaterplate,corrugated plate separator,feed water system and so on. Soda mixture come into the drum, first byunderwater plate, and then further separation by the corrugated plate separator, after that it lead out.

2. Evaporating heating surface is composed by the inlet and outlet header and the membrane wall.Theheader is made ofФ219 steel tube. The membrane wall is made ofФ60 tube and welded steel.

3.boiler pipes

The boiler drum installs safety valve, pressure gauge,water table, continuous blowdown, dosing valve andso on.

4.furnace wall

This boiler adopts light furnace wall.So as to improve boiler effiency,reduce furnace wall leakage,reduceheat loss from the boiler.The drum insulation thickness is about 100-120mm. All leads, down tube and pipeinsulation thickness is 80mm.The material is calcium silicate insulation coating.

5. water quality and export steam quality requirements.

Boiler feed water and boiler water indicators should be consistent GB1576-2001.

Boiler feed water and boiler water indicators should be consistent GB1576-2001

We by the abundant technical force, perfect detection means, strict quality management, sophisticated processing equipment, has its place in the same industry. Our company strictly abide by equality and mutual benefit, quality first, customer supreme principle, is willing to provide warm and thoughtful pre-sale service.

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!