|

Zhengzhou Boiler Co., Ltd.

|

75 t/h Mediate Temperature and Pressure Circulating Fluidized Bed Boilers

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

75 t/h Circulating Fluidized Bed Boilers adopts a new type of high efficiency, low polluting clean coal technology, fuel pretreatment system

75 t/h Mediate Temperature and Pressure Circulating Fluidized Bed Boilers

75 t/h Circulating Fluidized Bed Boiler adopts a new type of high efficiency, low polluting clean coal technology, fuel pretreatment system

We by the abundant technical force, perfect detection means, strict quality management, sophisticated processing equipment, has its place in the same industry. Our company strictly abide by equality and mutual benefit, quality first, customer supreme principle, is willing to provide warm and thoughtful pre-sale service.

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

75 t/h Circulating Fluidized Bed Boilers adopts a new type of high efficiency, low polluting clean coal technology, fuel pretreatment systemModel No.:ZG Series

Fuel:Ⅱ bituminous coal,anthracite Usage:power station Pressure:mediate pressure Type:natural circulation Place of Origin:Henan,China (Mainland) Output:75 t/h Structure:water tube Style:vertical

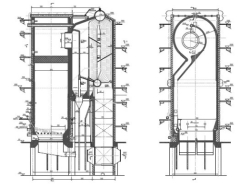

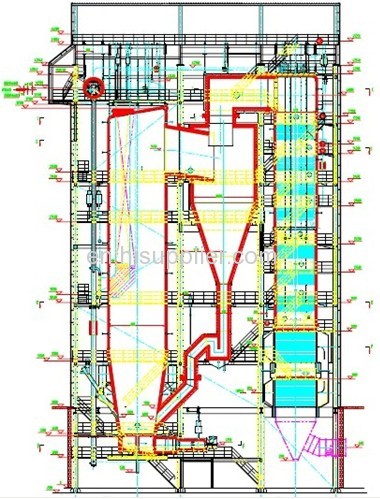

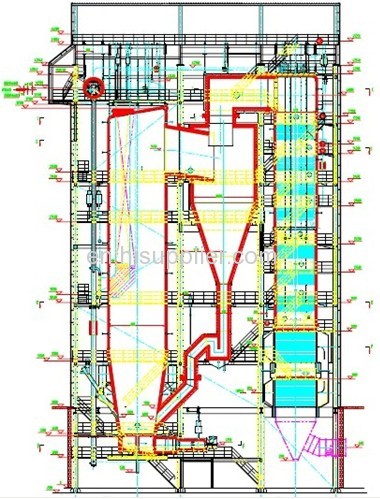

75 t/h Mediate Temperature and Pressure Circulating Fluidized Bed Boiler has the feature of good fuel suitability, high combustion efficiency,small furnance section,well load regulation performace.high efficiency desulfurization, low Nox emissions, simple fuel pretreatment system, low investment and stir cost. Circulating fluidized bed adopts higher fluidized speed than bubbling bed, a large number of materials is sent to the furnance upper,through the separator of the furnance outlet,separat the material and flue gas.The material is sent back to bed through no-mechanical anti-feeders.It has large thermal capacity and good material mixture,the fuel is 1%3% of bed material,the rest is searing bed material. Even if the fuel of difficult to fire,it can mix with searing bed material quickly.It can be heated to fire temperature.Due to strong turbulence and material circulation in the bed, it extends the burning stay time.Fuel is sent back to the combustion chamber through separator.It can reduce the carbon content of fly ash.The combustion efficency of circulating fluidized bed is 97%~99%.The operation temperature of circulating fluidized bed is 850~950.Limestone and desulfurizer can greatly reduce SO2 emissions.Circulating fluidized bed adopts low temperature classification air combustion.The combustion is under the low excess air.It reduces the content of NOX.The concentration of circulating fluidized bed material is high. Circulating material send high heat transfer coefficient,the boiler load regulation range is large,the circulation consistent with boiler load changes.Boiler can keep rated temperature and pressure.it can operation station under lower load.It doesnot increase the auxiliary fuel.

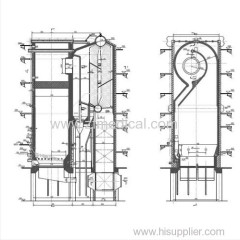

75 t/h Circulating Fluidized Bed Boilers adopts a new type of high efficiency, low polluting clean coal technology, fuel pretreatment system75 t/h Mediate Temperature and Pressure Circulating Fluidized Bed Boiler proper is composed by combustion equipment,feed coal device,water cool system,high temperature cyclone separator,superheater,air preheater,steel frame,escalator,furnance wall and so on.

75 t/h Circulating Fluidized Bed Boilers adopts a new type of high efficiency, low polluting clean coal technology, fuel pretreatment system

75 t/h Circulating Fluidized Bed Boilers adopts a new type of high efficiency, low polluting clean coal technology, fuel pretreatment system

Basic characteristics of ZG Series75 t/h Mediate Temperature and Pressure Circulating Fluidized Bed Boiler

1.boiler specification

Index | Parameter |

rated evaporation capacity | 75t/h |

rated steam temperature | 450℃ |

rated steam pressure | 3.82MPa |

feed water temperature | 104-150℃ |

exhaust gas temperature | -128.7℃ |

design thermal efficiency | 88.9 % |

2. Design fuel isⅡ bituminous coal,anthracite

Available fuel:Qnet>14Mj coal fuel

Fuel partical requirement:coal is 0~10mm.

Limestone partical requirement is less than 1mm.

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Boilers

Temperature Pressure Gauge

Pressure Temperature Gauge

H Beam

Circulating Pump

Circulating Water

More>>