|

Zhengzhou Boiler Co., Ltd.

|

circulating fluidized bed boiler system

| Special Groups: |

steam boilers (44)

|

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

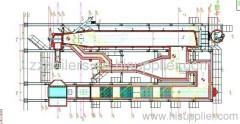

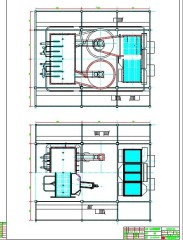

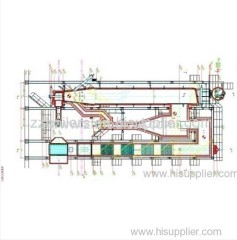

Introduction to The CFBC Boiler Room Process(1) Boiler System

Introduction to The CFBC Boiler Room Process(1) Boiler System

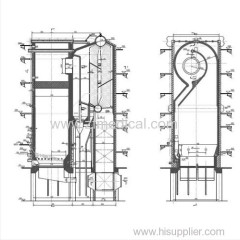

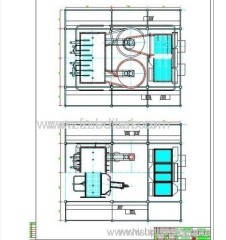

Introduction to The CFBC Boiler Room Process(1) Boiler System includes boiler proper, Anti-canopy, valves and instruments, pressure reducer, forced draft fan, induced draft fan, feed water pump, dust collector, PLC control system, coal feeder, sub-cylinder.

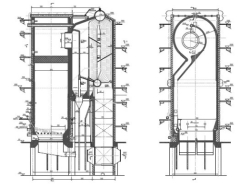

1.The use of membrane water cooling wall to layout the combustion chamber,separator and fly back feeding system into one,has compact structure, the separator has unique structural design.A.separator use of membrane wall to form the framework, structure is stable.B.the membrane wall can absorb heat of the lining,allowing residual carbon in the flue gas to continue burning in the separator,will not cause coking and enhance the separation efficiency.C.membrane wall are welded inverted fork type grasping nails,wear-resistant material forming cast to ensure a smooth inner surface of the seperator,and is a special streamlined,separation efficiency is as high as 97.97%,cutting diameter dc is for 8-15um.D.lined with abrasion-resistant material with thickness of 80mm,of small thermal inertia,at the same time can prevent cracks,and meet the requirement of the circulating fluidized bed boiler to start and stop quickly.increase the spiral separator diffuser can extend the entrance of accelerating section,to ensure that the entrance of large particles can be pre-separated particles to improve the separation efficiency separator to make up for the

burning of coal particles in the chamber enough to improve combustion efficiency.Offset center tube can tend to flow cross-sectional area smaller,the location of the gas flow after the first speed reducer,so that more of the solid particles left behind to the wall to be separated to improve separation efficiency.

2.The layout improvement of heating surface.Optimize the layout of the horizontal pipe laying,reduce abrasion of the pipe laying and extend running time.Enhance the position of pipe laying,reduce the wear of pipe laying,additional maintenance space,easy maintenance.Sewer put in operation layer,easy layout of sewage pipes.

Introduction to The CFBC Boiler Room Process (1) Boiler System

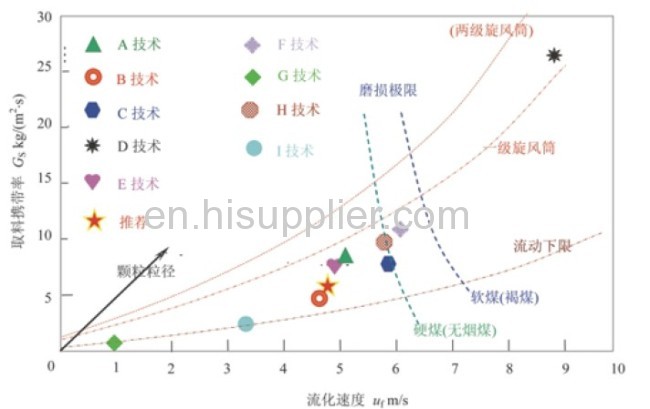

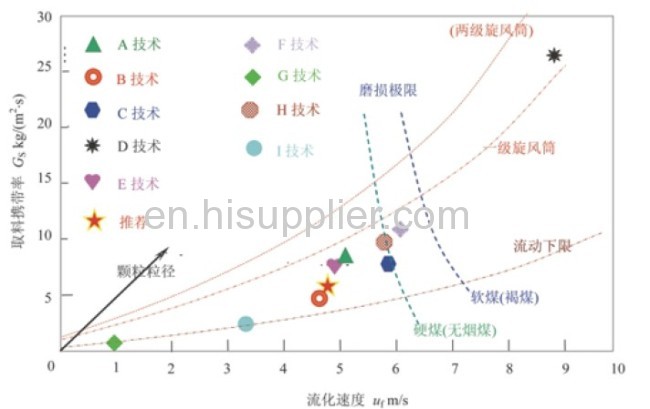

Energy-saving Circulating Fluidized Bed Boiler takes the principle of stationary design and circulating fluidized bed map as the guide,the theory of material balance and the theory of particle fuel combusition and a more substantial reduction in the total bed stock,thus form the flow pattern based on the re-structure of Energy-saving Circulating Fluidized Bed Boiler technology.It represents the latest developments direction of the circulating fluidized bed technology.

·Fluidized speed

The structure features of Energy-saving Circulating Fluidized Bed Boiler is :

1 The structure of a single drum Energy-saving Circulating Fluidized Bed Boiler transverse type

2 The suspension furnace of energy-saving circulating fluidized bed boiler equipped with film water-cooled wall and the imports of separator is water-cooled flue

3 The use of bell hood of Energy-saving Circulating Fluidized Bed Boiler that 's easy to replace,low resistance,non-inverted gray

4 The separator and the center tube of energy-saving circulating fluidized bed boilerhave the technological improvements for low resisitance,high separation efficiency

5 The use of patented technology and equipped with independent device of roots blower to save power consumption

6 The use of low bed pressure operation.

7 The use of lower pressure fans,reducing the power consumption of fans

8 Optimization of secondary air layout and flow vents to reduce the secondary air pressure of fans

9 To improve the fuel crusher and screening system,the coal particalsize is in line with design requirements

10 The air preheater use of a multi-tube boxarrangement,and low-temperature use of corrosion-resistant steel to avoid the corrosion due to low temperature cause to replace the whole.

The technical characteristics of ZG Series Energy Saving Circulating Fluidized Bed Boiler is:

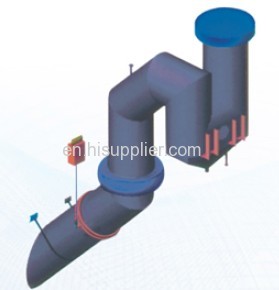

·back feeder device

3. Whirlwind seperator of low resistance,high efficiency

burning of coal particles in the chamber enough to improve combustion efficiency.Offset center tube can tend to flow cross-sectional area smaller,the location of the gas flow after the first speed reducer,so that more of the solid particles left behind to the wall to be separated to improve separation efficiency.

2.The layout improvement of heating surface.Optimize the layout of the horizontal pipe laying,reduce abrasion of the pipe laying and extend running time.Enhance the position of pipe laying,reduce the wear of pipe laying,additional maintenance space,easy maintenance.Sewer put in operation layer,easy layout of sewage pipes.

Introduction to The CFBC Boiler Room Process (1) Boiler System

Energy-saving Circulating Fluidized Bed Boiler takes the principle of stationary design and circulating fluidized bed map as the guide,the theory of material balance and the theory of particle fuel combusition and a more substantial reduction in the total bed stock,thus form the flow pattern based on the re-structure of Energy-saving Circulating Fluidized Bed Boiler technology.It represents the latest developments direction of the circulating fluidized bed technology.

·Fluidized speed

The structure features of Energy-saving Circulating Fluidized Bed Boiler is :

1 The structure of a single drum Energy-saving Circulating Fluidized Bed Boiler transverse type

2 The suspension furnace of energy-saving circulating fluidized bed boiler equipped with film water-cooled wall and the imports of separator is water-cooled flue

3 The use of bell hood of Energy-saving Circulating Fluidized Bed Boiler that 's easy to replace,low resistance,non-inverted gray

4 The separator and the center tube of energy-saving circulating fluidized bed boilerhave the technological improvements for low resisitance,high separation efficiency

5 The use of patented technology and equipped with independent device of roots blower to save power consumption

6 The use of low bed pressure operation.

7 The use of lower pressure fans,reducing the power consumption of fans

8 Optimization of secondary air layout and flow vents to reduce the secondary air pressure of fans

9 To improve the fuel crusher and screening system,the coal particalsize is in line with design requirements

10 The air preheater use of a multi-tube boxarrangement,and low-temperature use of corrosion-resistant steel to avoid the corrosion due to low temperature cause to replace the whole.

The technical characteristics of ZG Series Energy Saving Circulating Fluidized Bed Boiler is:

1. low-resistance,will not be brought down gray of bell-type hood

The Bell hood using of unique anti-wear technology,even wind and small resistance,do not wear.Solve the problem of the gray backward to ensure the combustion efficiency of the boiler.

·Air cap

·Air cap

2. Automatically adjusted back feeder of high flow rate and low-power

To use high-flow,low-resistance device is expected to choose the roots blower of the smaller power,at the same time can save power consumption for customers in ensuring safe and reliable operation of the cycle.

·back feeder device

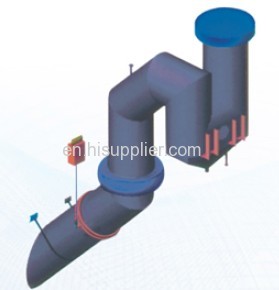

3. Whirlwind seperator of low resistance,high efficiency

The new generation super-efficient cyclone after the technological improvement,d50 value of 12 microns.d99 value of 100 microns.Separation efficiency of more than 99.6%,and the total resistance of less than 1100pa.

The cycle combustion system that's composed by bell hood,super high efficiency cyclone separator and materials returned device,can achieve reliable operation under the wind chamber pressure of 6-8KPa,can save more than 30%of power consumption for the customers.In the operation conditions of low air pressure of chamber,can save more than 5%of power consumption.

·Cyclone

·Cyclone

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Boiler

Circulating Pump

Circulating Water

Water Circulating Pump

Hot Water Circulating Pump

Solar Circulating Pump

More>>