|

Zhengzhou Boiler Co., Ltd.

|

Natural circulation Gas Boilers

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The avaliable fuel of Natural circulation Gas Boilers is blast furnace gas. It has the advantages of high thermal efficiency,stable output.

The avaliable fuel of Natural circulation Gas Boilers is blast furnace gas. It has the advantages of high thermal efficiency,stable output.

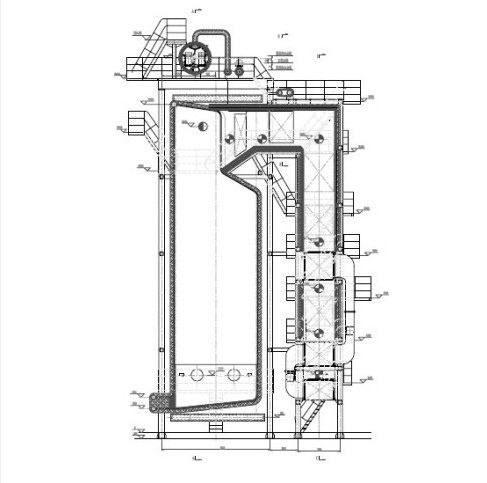

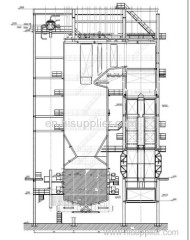

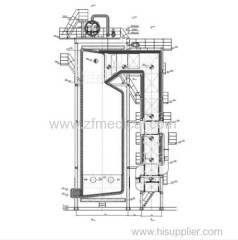

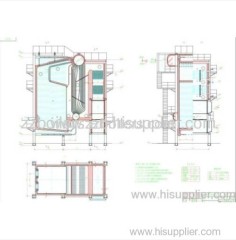

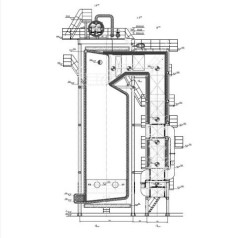

Natural circulation Gas Boilers are a medium-pressure parameters main combustion furnace gas natural circulation boilers. According to the outdoor layout, the design seismic intensity of theNatural circulation Gas Boilers is 7 degrees. The overall layout is in "Π" type and the superheater is suspended in the boiler roof. The Natural circulation Gas Boilers' economizer, air preheater branch are in the tail steel frame in order to facilitate maintenance.

The features of ZG Series 35 t/h Gas Boiler is :

1. The furnace adopts whole membrane wall structure, which has a good sealibility.

2. The various parts of the Natural circuation gas boilers' heating surface have sufficient maintenance space , which is convenient for the boilers' overhaul. The upper boiler can be set with canopy arranged in the outdoors, saving the boiler's room construction costs.

Natural circulation Gas Boilers are a medium-pressure parameters main combustion furnace gas natural circulation boilers. According to the outdoor layout, the design seismic intensity of theNatural circulation Gas Boilers is 7 degrees. The overall layout is in "Π" type and the superheater is suspended in the boiler roof. The Natural circulation Gas Boilers' economizer, air preheater branch are in the tail steel frame in order to facilitate maintenance.

The features of ZG Series 35 t/h Gas Boiler is :

1. The furnace adopts whole membrane wall structure, which has a good sealibility.

2. The various parts of the Natural circuation gas boilers' heating surface have sufficient maintenance space , which is convenient for the boilers' overhaul. The upper boiler can be set with canopy arranged in the outdoors, saving the boiler's room construction costs.

Basic characteristics of Natural circulation Gas Boilers

1.boiler specification:

rated evaporation 35 t/h

superheated steam temperature 450 ℃

superheated steam pressure 3.82 MPa

superheated steam pressure 3.82 MPa

drum working pressure 4.2 MPa

feed water temperature 104 ℃

exhaust gas temperature 163 ℃

boiler design efficiency 85.5%

type of fuel blast furnace gas

fuel consumption 35396.5Nm3/h

Safe and stable operation conditions range of the boiler:

gas pressure: 3000Pa-6000Pa,

heat load: 55%-110%.

2.basic dimensions:

drum elevation 19450mm

furnance width 3540mm

furnance depth 4310mm

boiler width 5640mm

boiler depth 9280mm

Introduction of ZG Series 35 t/h Gas Boiler proper structure

Introduction of ZG Series 35 t/h Gas Boiler proper structure

1. The boiler fuel used for the blast furnace gas is mixed with explosive air, so it adopts four burners arranged in both sides of the wall to form a hedge flame. It can not only ensure full combustion of the fuel gas, but also prevent the fuel gas and air mixture within the burner. The frame is made from steel and the tail is in a stacked structure. The drum interior adopts cyclone structure and the platform is in grid structure.

2. Fuel: blast furnace gas. The low calorific value of the designed fuel gas is 3269.8KJ/Nm3.

The main component is designed in the table:( %)

H2 | CO | CH4 | N2 | O2 | CO2 | H2S | CmHn | C2H4 | C3H8 | C3H6 | C4H10 |

1.8 | 23.5 | 0.3 | 56.9 | 0 | 17.5 | - | - | 0 | - | - | - |

3. In order to ensure the quality of steam standard, the boiler's feed water should meet GB/T12145-2008.

4. The Natural circulation Gas Boilers adopt single drum structure and the drum diameter is 1400 mm with Q345R steel plate.The separator pot is 14 in diameter Φ290 cyclone, each cyclone load is about 3 tons / hour, the second separation was arranged on the top of the drum "V" shaped steel wire separator.

5. The Furnace section is 4340 × 3540 mm (according to waterwall centerline) rectangle. The burner is disposed on the side wall of the furnace wall, forming an L-shaped flame in the furnace hedge. The water wall is composed by Φ51 * 5 waterwall tubes and welded steel group. It is segmented slice out of factory and site assembly.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Gas Fired Boilers

Gas Water Boilers

Natural Gas

Boilers

Natural Gas Generator

Liquefied Natural Gas

More>>