|

Zhengzhou Boiler Co., Ltd.

|

Water tube 280 t/h Circulating Fluidized Bed Boilers

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Water tube 280 t/h Circulating Fluidized Bed Boilers adopt a new type of high efficiency, low polluting clean coal technology.It is the most practical

Water tube 280 t/h Circulating Fluidized Bed Boilers adopt a new type of high efficiency, low polluting clean coal technology.It is the most practical

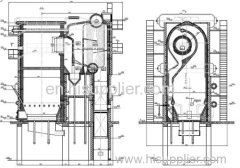

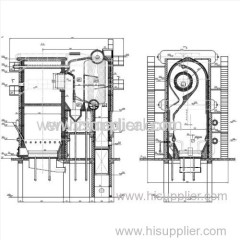

Water tube 280 t/h Circulating Fluidized Bed Boilers main feature is that the furnace contains a lot of material, large quantities of materials are carried by flue gas from combustion processes to the upper chamber,through the separator at the furnace outlet, separate items from the flue gas , echo valve materials through non-mechanical echo, multiple times loop combustion. Due to the high concentrations of materials, items with a large thermal mass and good mixing, capable of carrying several kilograms of flue gas per kg of material, these circulating materials have caused high heat transfer coefficient, expand the boiler heat load adjustment range, strong fuel adaptability. Circulating Fluidized Bed Boiler uses higher speed of stream than drum bubble bed,and it do not have a obviously of bed surface like drum bubble bed, due to strongly of turbulence and material cycle within the bed, it strengths the fuel mixture and extend the fuel stay time in furnace, so it has more high of burning efficiency than drum bubble bed, it can stable run in low load without increased auxiliary fuel.

Water tube 280 t/h Circulating Fluidized Bed Boilers main feature is that the furnace contains a lot of material, large quantities of materials are carried by flue gas from combustion processes to the upper chamber,through the separator at the furnace outlet, separate items from the flue gas , echo valve materials through non-mechanical echo, multiple times loop combustion. Due to the high concentrations of materials, items with a large thermal mass and good mixing, capable of carrying several kilograms of flue gas per kg of material, these circulating materials have caused high heat transfer coefficient, expand the boiler heat load adjustment range, strong fuel adaptability. Circulating Fluidized Bed Boiler uses higher speed of stream than drum bubble bed,and it do not have a obviously of bed surface like drum bubble bed, due to strongly of turbulence and material cycle within the bed, it strengths the fuel mixture and extend the fuel stay time in furnace, so it has more high of burning efficiency than drum bubble bed, it can stable run in low load without increased auxiliary fuel.

Water tube 280 t/h Circulating Fluidized Bed Boilers running temperature usually keeps in 850-900℃ Zhijian, this is a ideal of desulfurization temperature interval, it uses furnace within desulfurization technology, join desulfurization agent (as limestone) within the bed, fuel and the desulfurization agent repeatedly cycle, repeatedly for cryogenic burning and desulfurization reaction, coupled with furnace within turbulence movement dramatic, Ca/S Moore is about for 2.2 Shi, it can makes around 90% desulfurization efficiency, greatly reducing SO2 of emissions volume. at the same time circulating fluidized bed adopts thermal rating air combustion, it burns always under the low excess air, greatly reducing NOX emissions and produce. Circulating fluidized bed boiler is high combustion efficiency, it can be fueled with inferior fuel, good boiler load control, ash is easy to comprehensive utilization of the advantages .Thus it obtains the rapid development in the world. With the increasingly stringent environmental protection, it generally agreed that the circulating fluidized bed boiler is by far the most practical and feasible of high efficiency and low emission coal-fired equipment.

Water tube 280 t/h Circulating Fluidized Bed Boilers are the most next-generation high efficiency energy environmental type circulating fluidized bed boiler products. It bases on our company production experience, combines some advanced of run data, and according to our company and domestic famous colleges cooperation development circulating fluidized bed boiler of experience, and domestic similar type circulating fluidized bed boiler run of success experience.

Water tube 280 t/h Circulating Fluidized Bed Boilers basic features

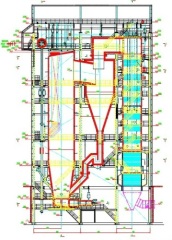

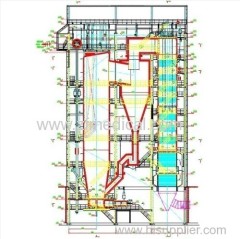

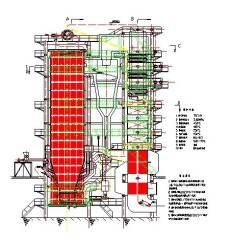

This boiler is high temperature ,high pressure,horizontal type with single drum, natural circulation, full suspension structures,full steel π layout. Operation layer is disposed on the elevation 8m.Steel platform is layout on the operation layer 5.4m.Boiler steel structure is main and cross-way (double column all steel),it is suitable for indoor and semi-open layout.Boiler is composed by furnance, adiabatic cyclone, self-balancing return valve,tail convection flue gas.Furnace adopts membrane wall.Boiler central is adiabatic cyclone.Tail shaft flue gas layout four group convection superheater.Three groups light pipe economizer and first,second air of two groups air preheater are layout under the superheater. Screen type superheater is layout before the furnace. It takes full advantage of the heat exchange with the circulating volume and characteristics of the combustion chamber temperature changes, making large-scale changes in boiler load steam parameters remain stable, it improves boiler operating at low load capacity.

Basic characteristics of Water tube 280 t/h Circulating Fluidized Bed Boilers

1.boiler specification

Index | Parameter |

rated evaporation capacity | 280t/h |

rated steam temperature | 540℃ |

rated steam pressure | 9.81MPa |

feed water temperature | 215℃ |

exhaust gas temperature | 141.9℃ |

normal blowdown rate | ≤1% |

air preheater inlet air temperature | 20 ℃ |

air preheater outlet hot air temperature | 173.7℃ |

air preheater outlet air excess coefficient | 1.25 |

design thermal efficiency | 90.77 % |

desulfurization effiency(furnace,Ca/S22.5) | ≥85 % |

fuel consumption | 66.8t/h |

first,second air volume rate | 6 :4 |

boiler fly ash bottom ash rate | 6 :4 |

Maximum dimensionsafter installation (m): | length×width×high=29.1×21.8×45.2 |

2. Design fuel is lignite. low calorific value of fuel is no less than 11710(2797)KJ/Kg.

Applicable fuel is bituminous coal,lean coal,anthracite,lignite, middlings,gangue and so on,ARB net calorific value Qnet..ar≥10.3MJ/kg(2460kcal/kg).

Coal granularity:different kind coal,coal granularityis in the furnace is different.The range of coal granularity is 0-10mm,50%cutting granularity diameterd50=1.5mm.Shown in the table below the recommended range:

| granularityrange (mm) | <0.5 | 0.53 | 35 | 58 | 810 |

| qualityshare (%) | 15 | 45 | 20 | 15 | 5 |

We by the abundant technical force, perfect detection means, strict quality management, sophisticated processing equipment, has its place in the same industry. Our company strictly abide by equality and mutual benefit, quality first, customer supreme principle, is willing to provide warm and thoughtful pre-sale service.

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Circulating Water

Water Circulating Pump

Hot Water Circulating Pump

Gas Water Boilers

Boilers

Water Bed

More>>