|

Zhengzhou Boiler Co., Ltd.

|

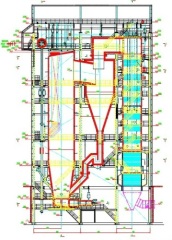

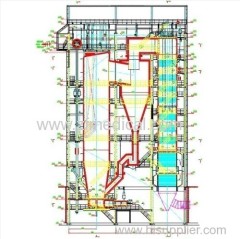

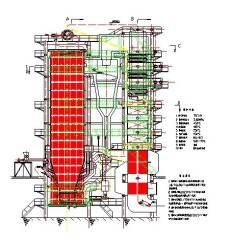

Vertical SHX Series Circulating Fluidized Bed Boilers

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Vertical SHX Series Circulating Fluidized Bed Boilers

Model No.:SHF series

Usage:Industrial

Pressure:low pressure

Type:Forced Circulation

VerticalSHX Series Circulating Fluidized Bed Boilers

We by the abundant technical force, perfect detection means, strict quality management, sophisticated processing equipment, has its place in the same industry. Our company strictly abide by equality and mutual benefit, quality first, customer supreme principle, is willing to provide warm and thoughtful pre-sale service.

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

VerticalSHX Series Circulating Fluidized Bed Boilers

Model No.:SHF series

Usage:Industrial

Pressure:low pressure

Type:Forced Circulation

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

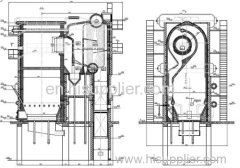

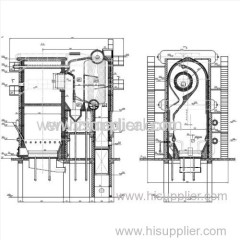

The advantage of SHX Series Energy Saving Circulating Fluidized Bed Boiler is:

1.increase the separation of spiral diffuser inlet and offset center tube

Increase the spiral separator diffuser can extend the entrance of accelerating section,to ensure that the entrance of large particles can be pre-separated particles to improve the separation efficiency separator to make up for the burning of coal particles in the chamber enough to improve combustion efficiency.Offset center tube can tend to flow cross-sectional area smaller,the location of the gas flow after the first speed reducer,so that more of the solid particles left behind to the wall to be separated to improve separation efficiency.

2.The layout improvement of heating surface

Optimize the layout of the horizontal pipe laying,reduce abrasion of the pipe laying and extend running time.

Enhance the position of pipe laying,reduce the wear of pipe laying,additional maintenance space,easy maintenance.

Sewer put in operation layer,easy layout of seaage pipes.

3.Improvement of burning equipment

By improving the shape of the head of the hood and the circumferential direction of arrangement of the holes optimal design,on the one hand to extend the life of hood,meanwhile it can improve the situation of the flow hood area,avoid cloth wind board dead,improve the flow quality of layer.Moreover,there are two advantages by using this type of hood.One is to avoid the ash flowing back to wind box.And second,to avoid the use of Bell Shi hood O'clock slag particles into the Dao hat head and area between the inner tube can not clean up the problem.Thereby enhancing the overall performance of combustion equipment.

4.Optimization of slag drop tube

For SHX Series Energy Saving Circulating Fluidized Bed Boiler,the slag drop tube which in the furnace-side is easy to heat and deformation,leading to the boier can not operate normally disadvantages.If we improve the slag drop tube into dested structure.it can efectively prevent the deformation of pipe ends off the residue,even if problems are only partial replacement,easy maintenance.Java tube wear while off the air box office with flexible connection,to resolve residue management are inconsistent with the bellows expansion bellows tear caused by air leakage problems.Residue management structure tends to perfect.

5.Auxiliary feedback unit

As SHX Series Energy Saving Circulating Fluidized Bed Boiler is in operation,if the back feeding entrance blocked and the original structure can not be handled in time,the trouble of blocking willaffect the normal operation of circulatory system.Now increase dredging equipment at the back feeding entrance.The advantage is that we can observe whether the entrance is block or not at any time,and can plug in time eliminate failure to ensure normal operation of the circulatory system.

6.Optimal design of water system

7.By new design,water-cooled beam system and boiler water,cooling water system into a single pressure system to solve the water-cooled beam bum,leakage and other troubles.

SHX Series Energy Saving Circulating Fluidized Bed Boiler can meet customers'demands.

VerticalSHX Series Circulating Fluidized Bed Boilers

Model No.:SHF series

Usage:Industrial

Pressure:low pressure

Type:Forced Circulation

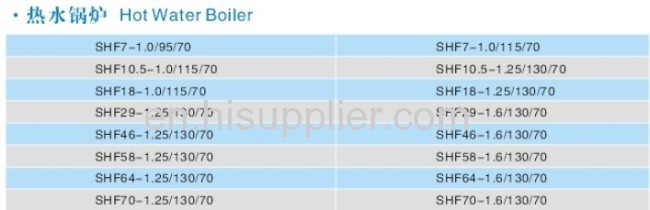

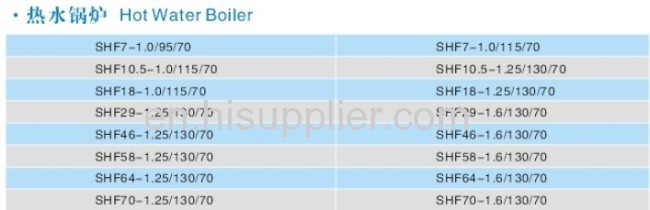

·Products List

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Electric Vertical Bed

Boilers

Circulating Pump

Circulating Water

Biomass Boilers

Electric Boilers

More>>