|

Zhengzhou Boiler Co., Ltd.

|

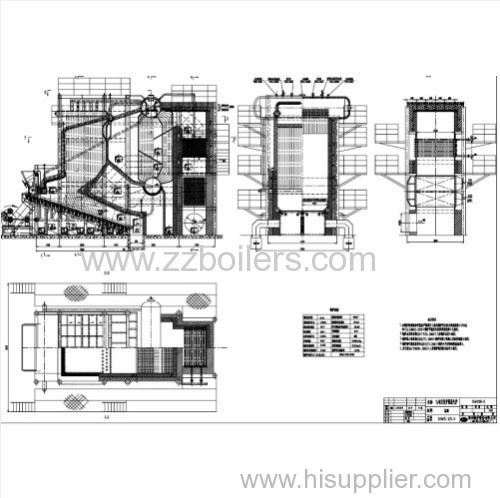

Field Assemble Reciprocating Grate Steam Boilers

| Payment Terms: | T/T |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Field assemble reciprocating grate steam boiler combustion equipment adopts reciprocating grate. It is a simple structure, convenient,.

Field Assemble Reciprocating Grate Steam Boilers

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

Field assemble reciprocating grate steam boiler combustion equipment adopts reciprocating grate. It is a simple structure, convenient,.

Products relying on a strong technical backing, in order to "health world, future" as the enterprise idea, with energy conservation and environmental protection products and services in health, laboratory and other high-end technology, for human health and the health of the world, set up the green channel, we have to "abide by the laws, the good faith management, quality first" as the basic principle, in order to "serve the society, the harmonious environment" as the professional attitude, efforts to create "health product", to provide customers with quality service.

Field assemble reciprocating grate steam boiler combustion equipment adopts reciprocating grate. It is a simple structure, convenient,.

SHW series field assemble reciprocating grate steam boiler combustion equipment adopts reciprocating grate. It is a simple structure, convenient,.

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

Field assemble reciprocating grate steam boiler combustion equipment adopts reciprocating grate. It is a simple structure, convenient,.

Products relying on a strong technical backing, in order to "health world, future" as the enterprise idea, with energy conservation and environmental protection products and services in health, laboratory and other high-end technology, for human health and the health of the world, set up the green channel, we have to "abide by the laws, the good faith management, quality first" as the basic principle, in order to "serve the society, the harmonious environment" as the professional attitude, efforts to create "health product", to provide customers with quality service.

Field assemble reciprocating grate steam boiler combustion equipment adopts reciprocating grate. It is a simple structure, convenient,.

Model No.:SHW Series Fuel:lignite, Ⅱ type bituminous coal,lean coal Usage:industrial factory,thermal power plant ,etc Pressure:low pressure Type:natural circulation Place of Origin:Henan,China (Mainland) Output:rated heat output:6-75t/h Structure:water tube Style:a horizontal type with double drums

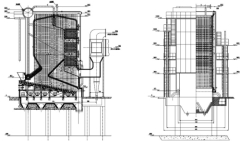

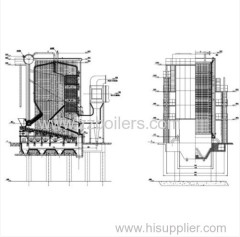

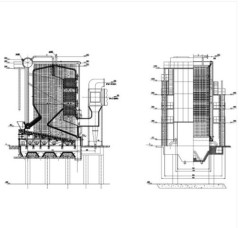

SHW Series Field Assemble Reciprocating Grate Steam Boiler Adopts the type of double-drum natural circulation water-tube, The furnace water wall tubes around the room layout to absorb radiant heat, it forms membrane wall water-cooling furnace. Chamber before and after the membrane water-wall tube to the lower part of the wall to stretch in the furnace respectively, it forms the arch above the grate , which increases the sealing performance of the boiler and the heating surface of the furnace, while reinforcing the strength of the arch after. Former and back arch to the fire after pouring refractories, to reduce heat absorption, to form high temperature area, it is enabling combustion of the fuel.

Furnace wall water-cooled wall tube in furnace export smoke window Department is pulled into two row, it constitutes coagulation slag bundle with boiler bundle.Flue gas through a baffle lateral scour convection tube from the bottom up. After cooling ,flue gas enter the boiler tail flue, scour tail-heating surface, through iron coal saver and air pre-heater, and then discharge furnace, into the dust collector, finally from chimneys into the atmosphere.

SHW Series Field Assemble Reciprocating Grate Steam Boiler combustion equipment adopts reciprocating grate. Due to the moving grate push feed, It can mix the burning and unburned fuels, it is greater grate ignited. Grate the push feed also play the flames .Because fuel particle wipe ,the outer layer of ash in coke-start fall off, the movable grate in while feeding also crush cinder blocks, which can make fuel better burn. It is a simple structure, convenient, smoke effects, smoke and low dust content.

SHW Series Field Assemble Reciprocating Grate Steam Boiler adopts balanced ventilation blowers and induced draft fans mode, it maintains negative combustion pressure 20Pa in the furnace, it is under negative pressure in the flue,it is conducive to environmental health.

We take the example of SHW15-1.25-H ,SHW Series Field Assemble Reciprocating Grate Steam Boiler. The design of boiler parameters:

()rated evaporation capacity: 15t/h

()rated steam pressure: 1.25MPa

()rated steam temperature: 194°C

()feed water temperature: 105°C

()air temperature: 30°C

()flue gas temperature: 132 ℃

()discharge rate: 5%

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!