|

Zhengzhou Boiler Co., Ltd.

|

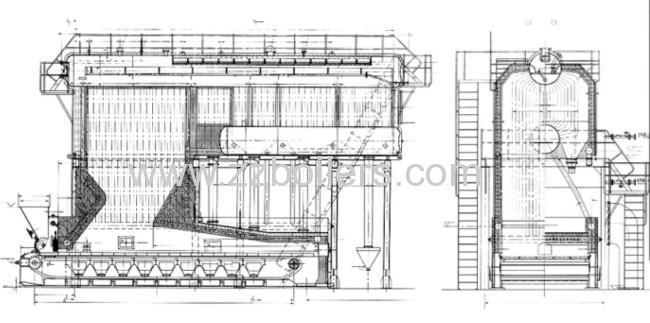

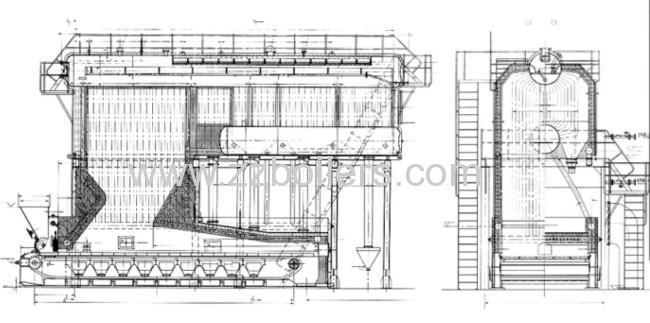

SZL series of 14 mw - 1.0 - / - 95/70 biomass hot water boilers

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to Basket | Add to My Favorites |

| HiSupplier Escrow |

Product Detail

SZL series of 14 mw - 1.0 - / - 95/70 biomass hot water boiler is a new type of pipe workshop assembly hot water boiler,adopting water-coolin.

SZL series of 14 mw - 1.0 - / - 95/70 biomass hot water boilers

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

Products relying on a strong technical backing, in order to "health world, future" as the enterprise idea, with energy conservation and environmental protection products and services in health, laboratory and other high-end technology, for human health and the health of the world, set up the green channel, we have to "abide by the laws, the good faith management, quality first" as the basic principle, in order to "serve the society, the harmonious environment" as the professional attitude, efforts to create "health product", to provide customers with quality service.

SZL series of 14 mw - 1.0 - / - 95/70 biomass hot water boiler is a new type of pipe workshop assembly hot water boiler,adopting water-coolin. Model No.:SZL Series

Fuel:corncob into blocks or bars shaped biomass fuel Usage:industrial Pressure:low pressure Type:natural circulation Place of Origin:Henan,China (Mainland) Output:14MW Structure:water tube

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.Main features:

1. Membrane water wall structure, front and rear arch, good sealability

2. Large volume and heating surface, high combustion efficiency

3. Light and large-size chain grates, straticulating combustion

4. Light boiler proper, saving transportation cost

Specific Design:

1. This product is double-drums vertical chain grate boiler, whose fuel is corncob blocks or bars. It's a high-efficiency energy-saving and environmental protection product.

2. The two sides of the furnace adopt membrane water-cooled wall structure. The tubes of water-cooled wall go down to the up side of the furnace,forming the front and rear arches so that the seal structure and intensity of back arch are enhanced and the cubic of the furnace and heating surface are enlarged.

3.There are end combustion chamber and convection tube tank in the back of the furnace with a fixing economizer in the rear. Through the furnace, end combustion chamber, convection tube tank and economizer, the flue gas comes into the flue duct in the rear, and then goes through dust precipitator, induced draft fan and chimney, and is discharged into the air in the end.

4. There is secondary air laid out in the front wall, which is controlled by valves and can be put into service to enhance the combustion and increase the combustion efficiency when biomass fuel is used as boiler fuel.

5. The height of feeding inlet is higher than usual to satisfy the need of biomass fuel.

Boiler Specification:

Rated power | 14MW |

Rated waterpressure | 1.0 MPa |

Rated watertemperature | 95℃ |

Return watertemperature | 70℃ |

Cold airtemperature | 20 ℃ |

Exhaust gastemperature | 155℃ |

Test pressure | 1.4 MPa |

Design thermalefficiency | 80.8% |

Grate area | 25.8 m2 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Biomass Boilers

Gas Water Boilers

Water Pump Series

Boilers

Hot Water Pump

Hot Water Dispenser

More>>